MSV International Engineering Fair – October 8, 2024 – October 11, 2024

- Promotion of AI MATTERS services and technology infrastructure with a focus on the Czech node.

- B2B Meetings with potential clients.

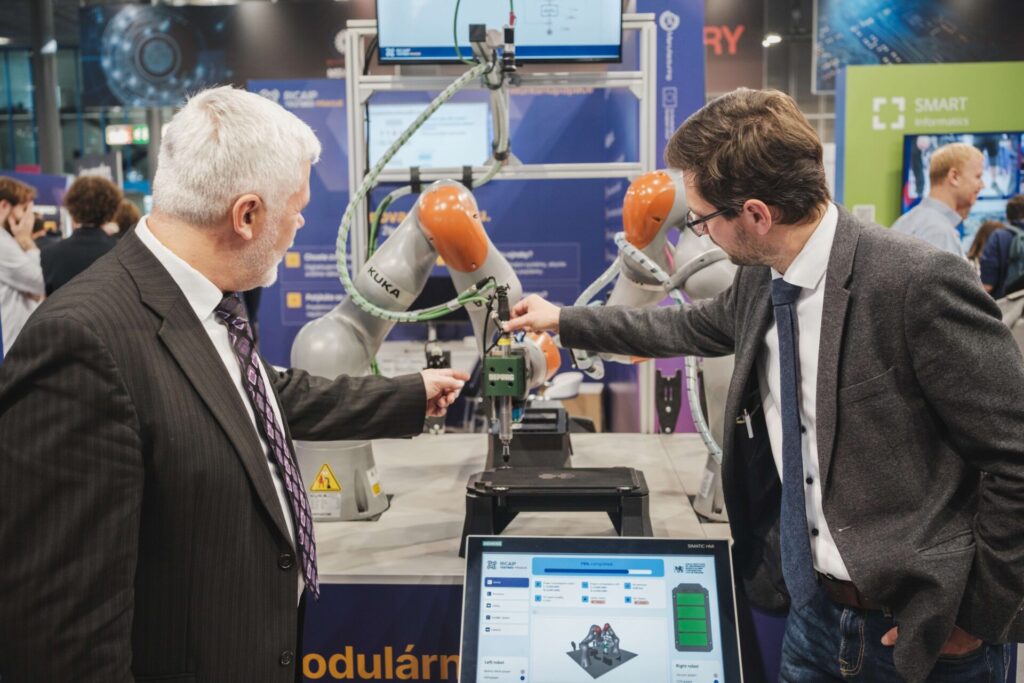

For the third time, the teams of CIIRC CTU and RICAIP Testbed Prague joined the joint exhibition of the National Centre for Industry 4.0 and its key partners at the International Engineering Fair in Brno – MSV Brno 2024!

Visitors could find there a range of technology demonstrations, innovations, and industry-focused solutions – the showcase featured a wide array of technological advancements and opportunities that help manufacturing companies thrive in the digital age.

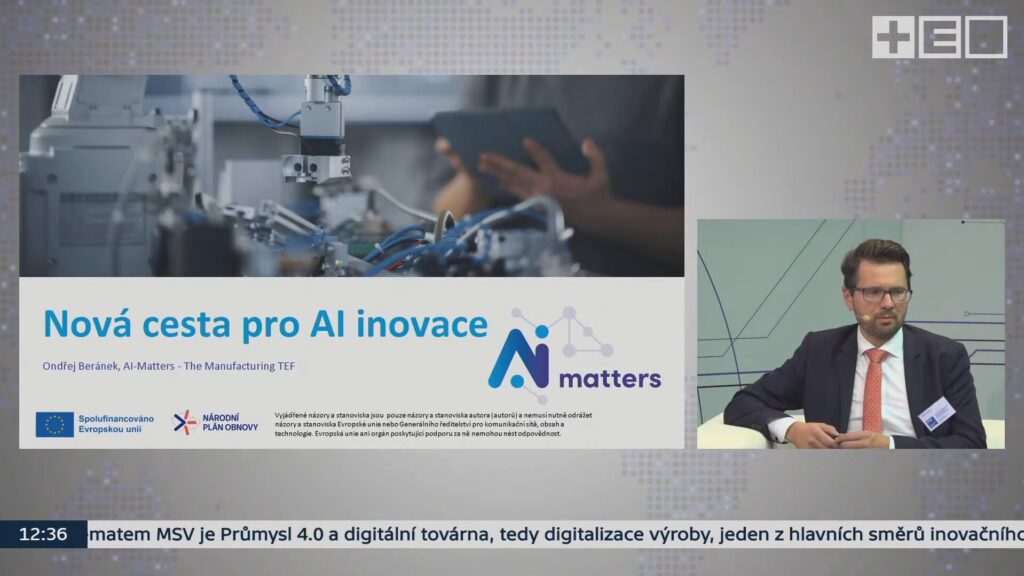

MSV DigiStage

Watch the discussion held at the MSV DigiStage on how RICAIP testbeds and AI-Matters contribute to the innovation and digital transformation of the Czech industry!

DIGINOVATION Conference

Our experts contributed significantly by presenting the latest projects and innovations in artificial intelligence and industry.

Ondrej Beranek highlighted how the AI-MATTERS project opens doors for companies to access the infrastructure and services of testbeds.

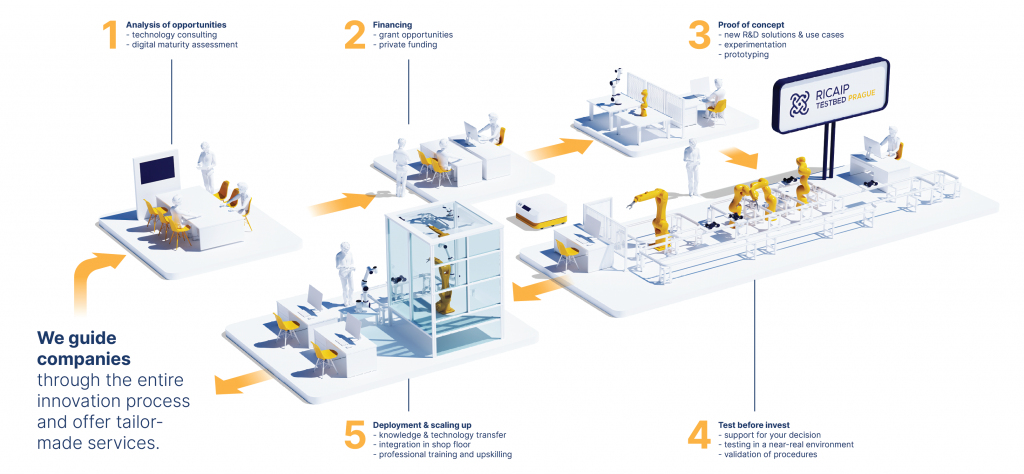

What CIIRC CTU Can Offer to Companies – Small, Medium, Large, and Start-Ups

- We assist modern companies with AI-based innovations by providing tailored solutions using our own and our partner teams’ capacities and expertise.

- Our services cover the entire innovation cycle: Whether you’re addressing a challenge in any stage of digitalization or implementing AI into your operations, we’ll find the right solution for you.

- Our experts will support you with development, testing, financing, implementation, and training of technical staff.

- We validate processes and their feasibility through simulations and virtual commissioning, enabling us to scale solutions and demonstrate how they will work in real-world operations.

- We provide various solution options based on required production capacity and other parameters.

- Our services help manufacturing companies overcome numerous challenges and ensure long-term competitiveness.

Available Resources

- Infrastructure: Access to our testbed and partner testbeds within the RICAIP center, equipped with state-of-the-art hardware and software.

- Cutting-edge Technologies: The latest technologies and methodologies.

- International Expertise: Access to academic and industrial experts in AI, robotics, and other deep tech fields.

- Data and Algorithms: Datasets, experimentation, and algorithms to develop optimal solutions.

- Training Programs: General, specific, and highly specialized programs in digital technologies.

- Funding Opportunities: Access to grants and other funding options.

- Tailored Services: Custom services for small and medium-sized enterprises through projects focused on AI and new technologies, such as EDIH CTU, AI-MATTERS, AIRISE, EIT Manufacturing, and more.

Through our partner ecosystem, you can also gain

- Digital Maturity Assessment

- Consultation and Digitalization Planning

- Access to New Technologies

- Long-term Financing

Why Collaborate With Us? We Guide You Through the Entire Innovation Cycle

- With our support, you gain expertise from our team and renowned partner organizations across Europe for safe navigation in new technologies.

- You can prototype and experiment with concepts and test them in a near-real environment using our equipment and technologies within the most advanced research infrastructure in Prague and other RICAIP testbeds.

- Test specific solutions before implementation without disrupting production.

- Improve and optimize your manufacturing operations.

- Leverage our strong international connections to find partners in the Czech Republic and abroad for further development and projects.

- Our solutions enable you to respond flexibly to market changes.

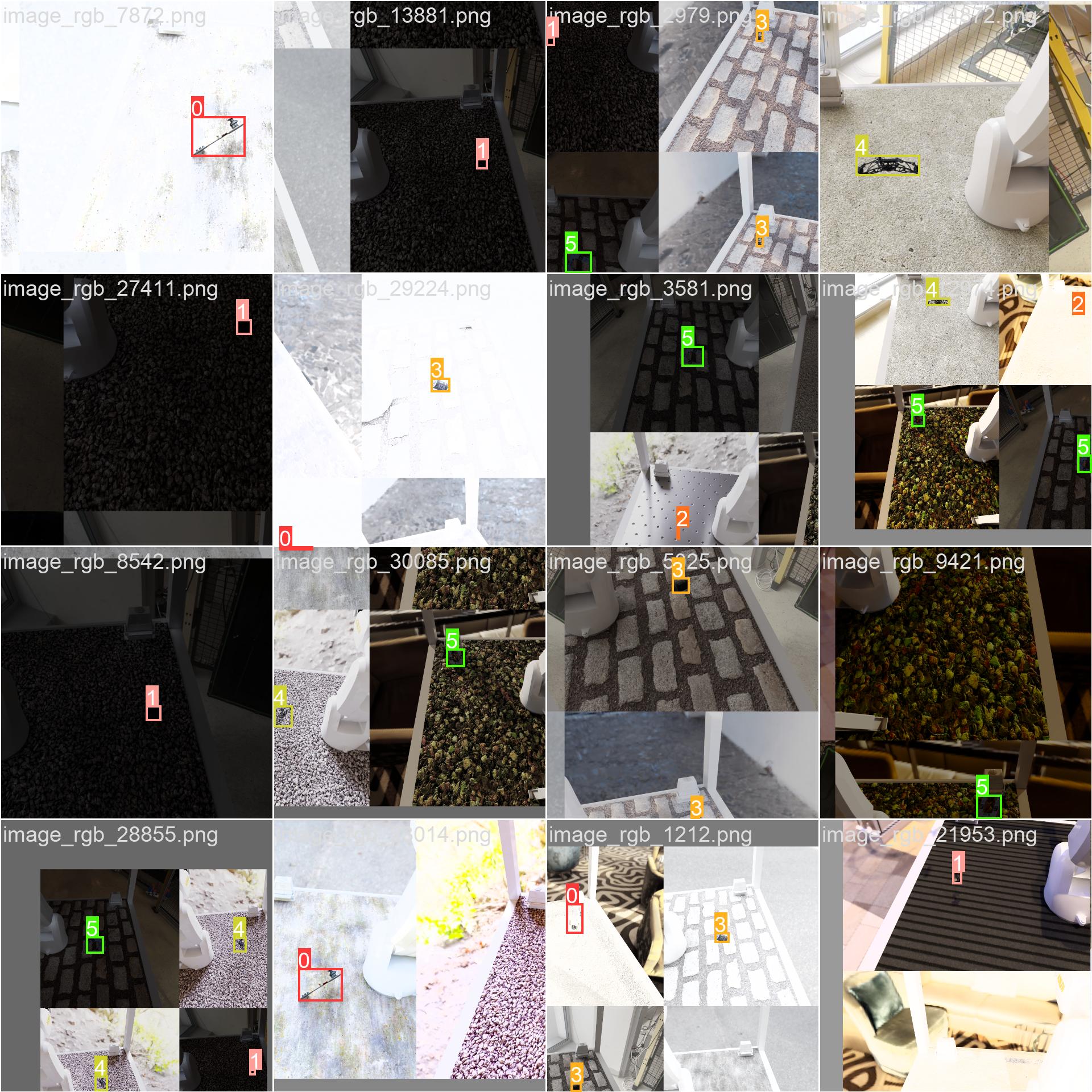

What was presented on the booth

Flexible Modular Robotic Cell: Retrofitting Battery Modules

This is a scaled-down model of an autonomous modular factory that adapts to changing production conditions. In just a few square meters, we demonstrate the key principles of modern, flexible, and sustainable manufacturing of the 21st century. We combine cutting-edge technologies and processes: intelligent collaborative robotics, data communication via a 5G network, edge computing, AI algorithms, computer vision, and autonomous control. All this is showcased through two KUKA collaborative robots that, without human intervention, exchange components and perform retrofitting on used battery modules, demonstrated on a scaled model of an electric vehicle battery. In real applications, these battery modules can continue to serve as large-capacity stationary batteries for homes or businesses.

Industrial Metaverse: Autonomous Manipulation Robotic Cell

The industrial metaverse is essentially an extended virtual reality that allows for the creation of a digital twin of a physical factory, machines, and products. It enables optimization of production processes, acceleration of product development, and enhanced collaboration between teams and robots. We demonstrate its potential with an autonomous manipulation robotic cell featuring a KUKA robot, performing precise pick-and-place operations, driven by advanced 6D position estimation using computer vision. The cell is virtually operated in Siemens’ Tecnomatix Process Simulate with integration into Nvidia Omniverse, allowing AI model training for object recognition and manipulation, and automated generation of end effectors through 3D printing. It’s also available in VR.

Sustainable Manufacturing: 5G IIoT and Machine Data Collection for Energy Consumption Monitoring

Data is all around us, but how can we collect, analyze, and use it to boost manufacturing efficiency, reduce costs, and enhance sustainability? At our stand, you’ll see this in real-time thanks to a compact modular 5G IIoT system, integrating energy consumption data across our entire display. Data transmission occurs over a 5G SA private campus network, with continuous monitoring of the 5G signal quality. A new feature is the NB IoT technology for water consumption measurement using a compact flowmeter, ideal for battery-powered devices.

Robotic Beer Dispenser 2.0

Our new Robotic Beer Dispenser 2.0 is fully automated and ready for continuous, unattended operation. It can pour four beers simultaneously and is equipped with AI to adapt to its surroundings and optimize energy consumption. Thanks to sensor feedback, the robot can actively adjust its movements while pouring beer. Advanced data analytics intelligently manage cooling and predict failures. Age verification can be ensured through facial recognition, making subsequent purchases automatic. This dispenser represents a cutting-edge solution for sustainable and smart beverage service using the latest technologies.

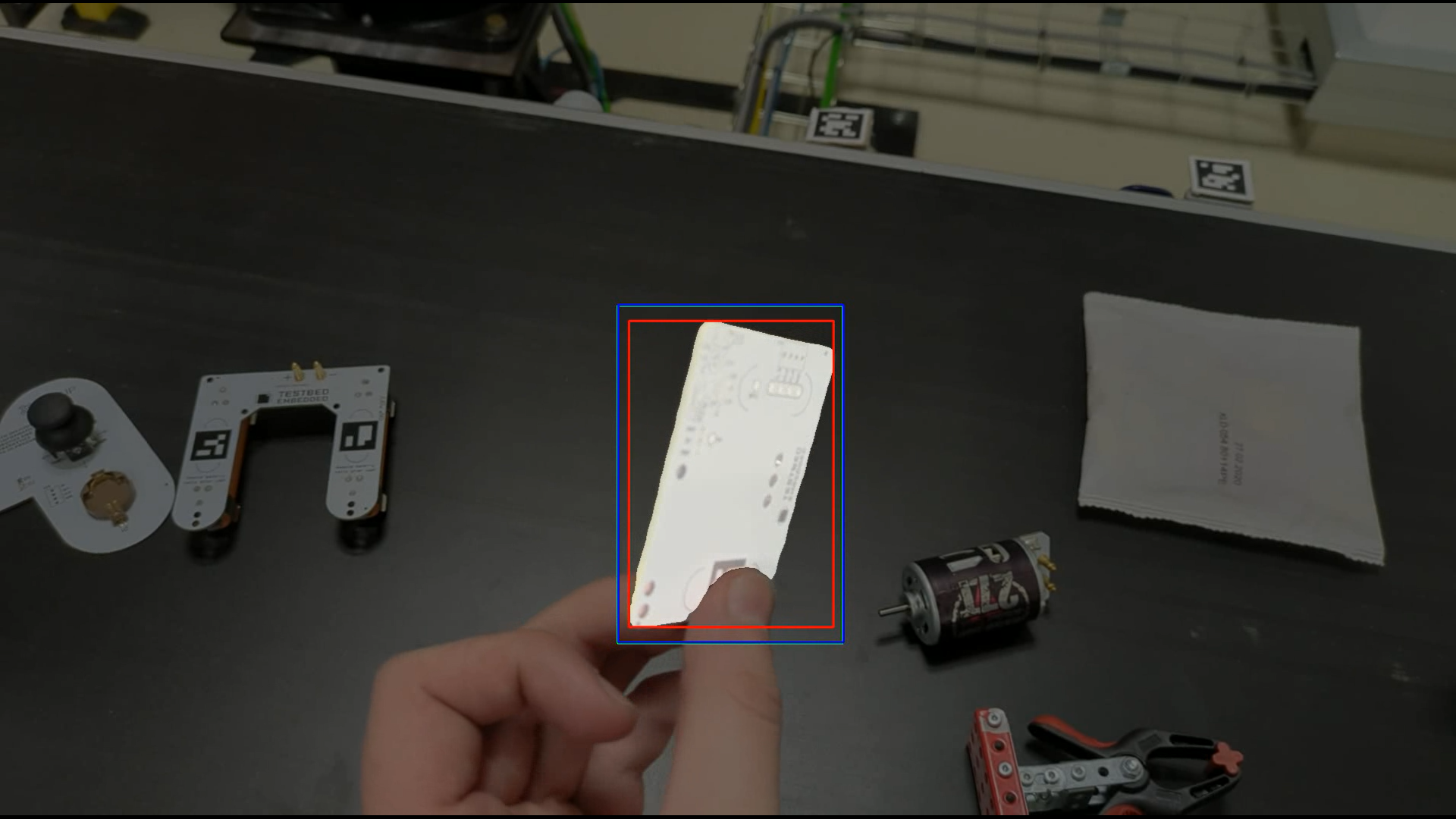

3D Object Reconstruction

We showcase how 3D object reconstruction aids in safely detecting objects for precise manipulation in unknown or changing environments. We developed an accessible and efficient device capable of spherical scanning using a standard RGB camera. The images are processed by our software into a 3D representation, allowing object detection, position estimation, and manipulation. We use an advanced 3D reconstruction algorithm that combines the power of computer graphics (Volume Rendering) and machine learning to create a 3D scene representation.